Inside industrial, commercial and residential environments, gas detection systems play a key role in ensuring safety. The presence of harmful gases can pose a threat to people and the environment. To ensure reliable operation of gas detection systems, a plan for maintenance must be implemented.

Why is maintenance in gas detection systems important?

Through regular maintenance of gas detection systems, the accuracy of measurements can be ensured, as sensors used in detection devices deteriorate over time due to contaminants in the environment or more simply due to wear and tear. Since gas detectors are designed to respond to certain levels of gas in the air, it is important to perform accurate calibration to avoid false alarms or unreported exceeded thresholds.

Proper maintenance allows you to:

- Extend the life cycle of the instruments

- Reduce environmental impact

- Reduce operating costs.

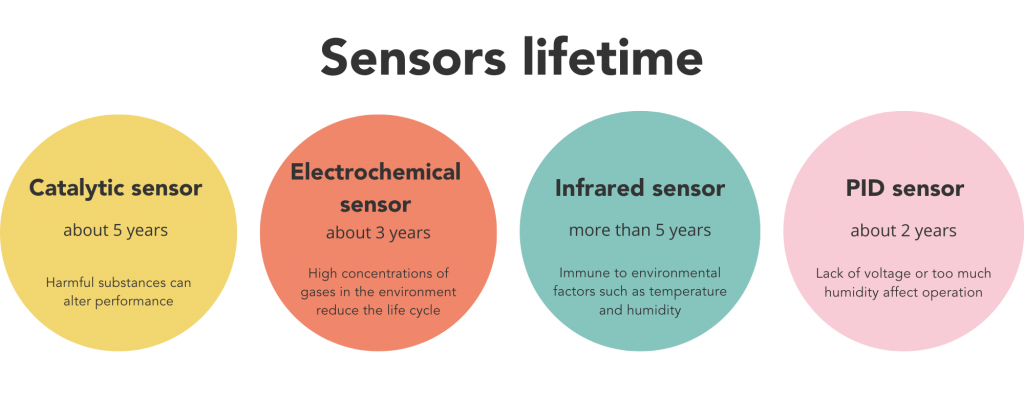

This last benefit should not be underestimated; in fact, a preventive intervention is often cheaper than repairing or, worse, replacing an entire system. Taking into account special circumstances where detectors are subject to harsh environmental conditions and sensors can be damaged in less time, timely replacement of worn or damaged parts can prevent sudden failures and reduce the risk of critical malfunctions. Depending on the type of detector installed and its sensor, maintenance may have different timelines and the frequency of calibration also varies depending on the environment in which they are installed.

The advantages of periodic maintenance in gas detection systems

Many industries are subject to stringent safety regulations, regular maintenance of gas detection systems is often a key requirement to maintain regulatory compliance. In addition to this, constant checks allow you to:

- prevent plant downtime

- guarantee the efficiency of gas detection systems

- ensure the safety of people and environments

The use of Augmented Reality

Though the use of augmented reality it’s possible to view our gas detectors in detail, open them to see the components and read technical details.

Our detectors in augmented reality are available on Instagram.

https://www.youtube.com/watch?v=8ob8YXNzXZU

Follow us on Linkedin

Follow us on Instagram