PID sensor and gas detection: how it works

Photoionization Detector (PID) sensors represent an advanced technology for the detection of volatile gases and volatile organic compounds (VOCs). Due to their sensitivity, reliability and versatility, these sensors are widely used in various industrial, environmental and security sectors.

PID sensors: how do they work?

PID sensors operate through the principle of photoionization. We can summarize their operation in three steps:

- Ionization: An ultraviolet (UV) lamp inside the sensor emits light at a specific wavelength. This UV light hits the target gas molecules, providing enough energy to ionize them.

- Detection: Ionized molecules produce ions and free electrons. These ions are collected by an electrode, generating an electric current.

- Measurement: The intensity of the electric current is proportional to the concentration of the target gas in the air. The sensor converts this current into a measurable signal, which is then interpreted and displayed.

PID sensors: where they are used

PID sensors find applications in a wide range of industries, including:

a wide range of industries, including:

- Industrial Sector: Used to monitor and detect hazardous gas leaks in working environments such as refineries, chemical plants and oil platforms, helping to prevent accidents and ensure worker safety.

- Environmental Monitoring: Used to detect VOCs and other air pollutants. These sensors help monitor air quality and ensure compliance with environmental regulations.

- Medical Sector: Employed to detect anesthetic gases and other volatile substances in hospital environments, helping to ensure the safety of patients and healthcare personnel.

- Leak Detection: Used in gas leak detection systems in buildings and infrastructure to prevent explosions or exposure to harmful substances.

PID sensors: advantages

PID sensors offer several advantages over other gas detection technologies:

PID sensors offer several advantages over other gas detection technologies:

- High Sensitivity: They can detect very low concentrations of gas, often on the order of parts per billion (ppb).

- Rapid Response: They provide nearly instantaneous measurements, making them ideal for applications that require immediate response.

- Wide Range of Detection: They can detect a wide range of volatile organic compounds and some inorganic gases, making them versatile for multiple applications.

- Portability: Many models are designed to be portable, allowing easy use in the field for environmental monitoring and safety.

PID sensors: durability and maintenance

The lifetime of a PID sensor depends on various factors, including the quality of the sensor itself, operating conditions, and frequency of use. However, key elements, such as the UV lamp, have life cycles ranging from 6 to 12 months, necessitating maintenance for replacement. In addition, depending on the manufacturer’s instructions, periodic calibration of the detector will also be necessary to ensure accurate detection.

Discover our products

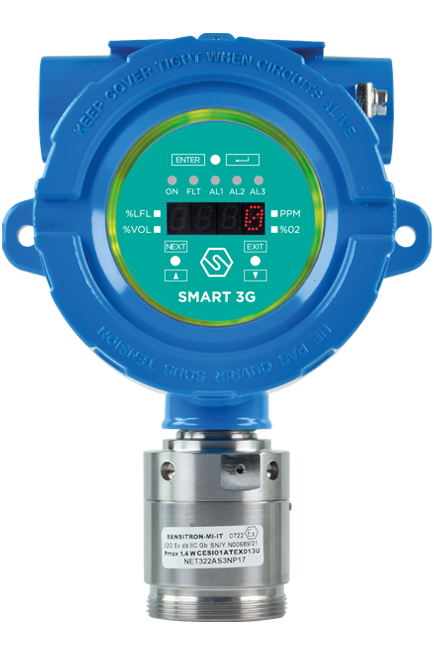

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.

Certified ATEX, IECEx and SIL2/3

SMART 3G D3

Suitable for detecting in classified areas, Certified ATEX, IECEx and SIL2/3, allows non-intrusive field calibration.

SMART 3G C2

Suitable for detecting, in classified areas, the presence of flammable substances (% LFL), toxic gases in ppm, refrigerant gases or for the detection of oxygen deficiency or excess.