Ammonia and gas detection: refrigeration systems

Ammonia (NH3) was one of the first refrigerants used and is still found in industrial refrigeration systems today. Despite the advent of synthetic refrigerants, ammonia remains a preferred choice for many applications due to its excellent thermodynamic properties and environmental benefits.

Ammonia: benefits and advantages

Energy Efficiency: Ammonia has a high heat capacity and better heat transfer efficiency than many synthetic refrigerants. This translates into reduced energy consumption for refrigeration systems, which is crucial for industries that operate on continuous cycles such as food and chemicals.

Environmental Impact: It’s a natural refrigerant with a global warming potential (GWP) of zero and an ozone depletion potential (ODP) also of zero. Unlike chlorofluorocarbon (CFC) and hydrofluorocarbon (HFC) refrigerants, ammonia does not contribute to climate change or ozone depletion.

Cost: It’s relatively cheap to produce and is not subject to the same price fluctuations as synthetic refrigerants. In addition, the superior energy efficiency of plants using ammonia results in significant savings in long-term operating costs.

Ammonia: main uses

Ammonia is widely used in various industries, including:

Ammonia is widely used in various industries, including:

- Food Industry: it is essential for refrigeration and freezing of food, ensuring the preservation and safety of perishable products.

- Ice Production: is used in ice production plants for commercial and industrial uses.

- Chemical Sector: It is used in critical cooling processes in chemical and petrochemical industries.

- Air Conditioning Systems: Ammonia also finds application in large centralized air conditioning systems, especially in industrial facilities.

Ammonia: the risks associated with its use

Ammonia has several aspects that need attention:

- Toxicity and Safety: A major drawback of ammonia is its toxicity. Exposure to high concentrations of ammonia can be dangerous to human health, making stringent safety measures necessary. However, modern plants are designed with leak detection and control systems that minimize the risk of exposure.

- Corrosivity: Ammonia can be corrosive to some metallic materials, particularly copper and its alloys. Therefore, plants should be constructed of corrosion-resistant materials such as stainless steel.

- Stringent Regulations: The use of ammonia is regulated by stringent regulations that vary from country to country. Companies must comply with these regulations, which may include specific design requirements, regular inspections and staff training.

Our ammonia detection products

For ammonia detection in refrigeration systems, Sensitron stationary gas detectors are ideal:

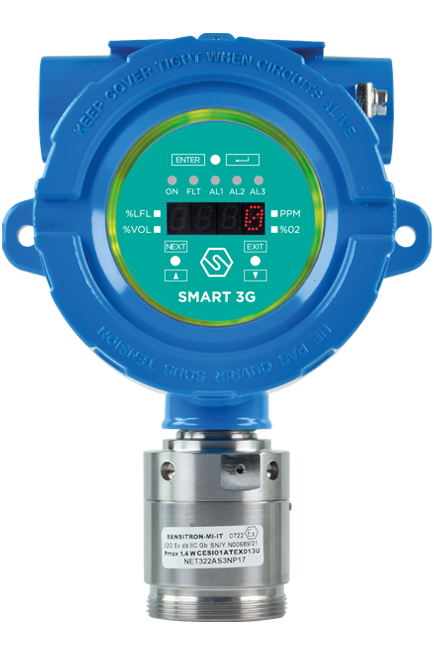

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.

Certified ATEX, IECEx and SIL2/3

SMART 3G D3

Suitable for detecting in classified areas, Certified ATEX, IECEx and SIL2/3, allows non-intrusive field calibration.

MULTISCAN ++S1/++S2

Designed to meet the widest demand from the market, they allow management of up to 264 detectors. ATEX and SIL certified.

Our certifications

Ammonia can be used within hazardous environments where strict safety standards must be observed, which is why all our products are certified and in line with regulations.

ATEX

The Directive establishes the requirements and evaluation of equipment intended for potentially explosive atmospheres.

IECEx

The IECEx system is an international certification system. It is developed by the International Electrotechnical Commission.

SIL2 (3)

The Safety Integrity Level (SIL) is the ability to reduce the assessed risk while ensuring the reliability of the safety systems.