Automotive industry and gas detection

In the automotive industry, gas detection is an essential technology for ensuring operator safety and reducing the environmental impact of production processes. Production plants and workshops are complex environments with numerous processes that can generate hazardous or harmful gas emissions. These include welding gases, solvent vapours, chemicals used in painting and even emissions from chemical reactions in materials processing.

Automotive industry: the advantages of gas detection

Within the automotive industry, the adoption of gas detection systems helps companies monitor these environments in real time, enabling them to quickly identify hazardous situations and take corrective action to protect workers and the surrounding area. Key benefits include:

- Worker Safety: Operators at automotive production sites are often exposed to potentially harmful gases, such as carbon monoxide (CO), nitrogen oxides (NOₓ), and volatile organic compounds (VOCs) emitted during welding, painting and assembly processes. Detecting these gases early is crucial to avoid poisoning or explosions.

- Protection of the Environment: Controlling industrial emissions helps minimise the environmental impact of automotive plants. Untreated harmful gases can contribute to air pollution and climate change.

- Operational Efficiency and Regulatory Compliance: Complying with environmental and safety regulations is crucial for automotive companies. The installation of advanced gas sensors allows real-time monitoring of emissions and ensures that pollution levels are always within imposed limits, avoiding penalties and production downtime.

Gas detection technologies in the automotive industry

Different types of sensors are used in the automotive sector, each designed to detect specific types of gas. Here are the most common ones:

- Catalytic Sensors: Primarily used for the detection of flammable gases, these sensors utilise the combustion of the gas on a catalytic surface. They are common in environments where there is a risk of the presence of flammable vapours, such as in painting and surface treatment areas.

- Electrochemical Sensors: These sensors are ideal for detecting toxic gases such as carbon monoxide (CO) and sulphur dioxide (SO₂). They are used in areas with combustion processes or in enclosed spaces where hazardous gases could accumulate.

- Infrared (IR) sensors: These sensors detect gases such as CO₂ and hydrocarbons by measuring the absorption of infrared light. They are particularly effective in monitoring industrial emissions and for keeping CO₂ levels in processing areas under control.

Automotive industry: the most common applications

Gas detection systems find application in several key areas within automotive production facilities:

- Paint Areas: Solvents and chemicals that emit volatile organic compounds (VOCs) and other toxic gases are used here. The detection of these gases allows concentration levels to be kept within safe limits, protecting both workers and the environment.

- Welding and Assembly Areas: These processes generate gases such as carbon monoxide, nitrogen oxides and ozone, all of which are potentially harmful. Sensors located in welding areas help maintain a safe environment for operators.

- Monitoring Emissions in Combustion Processes: In engine testing or vehicle testing departments, it is crucial to monitor exhaust gases. Gas sensors are placed to monitor CO₂, CO and NOₓ levels, ensuring that plants comply with emission regulations.

- Flammable Material Storage Areas: In these areas, the detection of hydrocarbon vapours and other flammable compounds is essential to prevent fires and explosions.

Our products for gas detection in the automotive industry

For gas detection within the automotive industry, the SMART 3G and SMART S series of gas detectors are ideal:

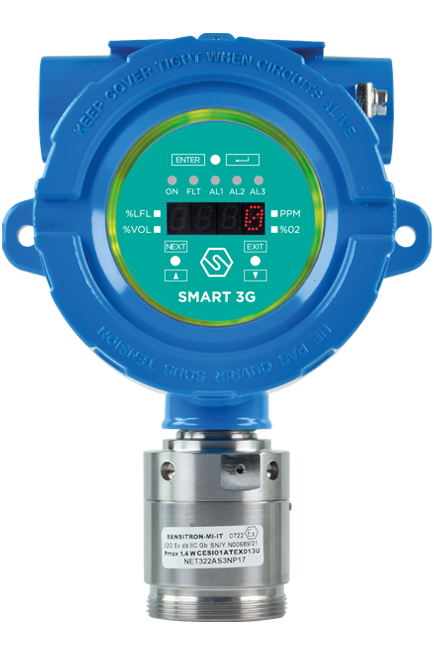

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.

Certified ATEX Category 2 for Zone 1, IECEx and SIL2/3

SMART 3G Gr.1

ATEX Group 1 certified, ideal for detecting flammable substances and toxic gases in mines, tunnels or areas classified Group 1.

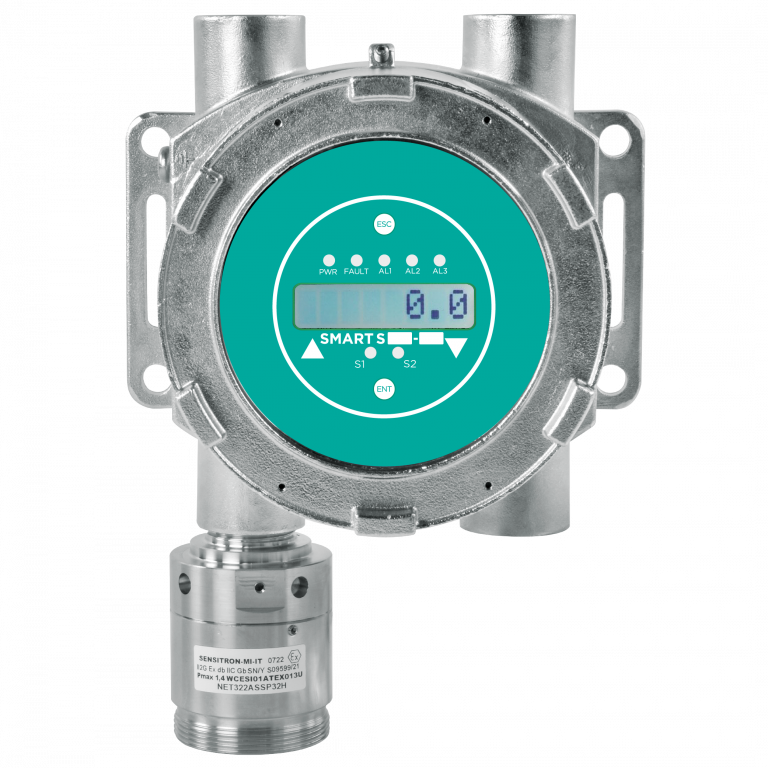

SMART S SS

ATEX certified for Zone 1, SIL2 Hardware and SIL3 Software, optional Hart Modem and with stainless steel housing.

Explore our spaces in virtual reality

Within the Sensitron metaverse you can explore application realities reconstructed in virtual reality. Find out more about who we are and what we do, walk inside a production area and learn more about the dangers of gas.