Conversion coefficient: why is it important?

During the calibration process, i.e. the process of adjusting and verifying the accuracy of a measuring instrument such as stationary gas detectors, we may find ourselves in the position of having to apply the conversion factor. Let us see together what it is and how it works.

Conversion factor: what it is

The conversion coefficient in gas detectors is a parameter used to convert the sensor reading from one reference gas to another gas. Each gas detector is calibrated to detect a specific gas, and the conversion coefficient indicates the proportion stored within the detector itself, which is necessary to perform a correct calibration of the SPAN. Together with each detector we sell, we supply a test certificate inside which you can read the value of the conversion coefficient.

Conversion Coefficient: When do you use it?

The conversion coefficient is very important during the SPAN calibration process, where in addition to the L.E.L. percentage of the cylinder being used for calibration, you will also be asked to select whether or not you are using the detector’s target gas. If you select no, the detector will automatically use the conversion coefficient (stored in the device) and perform the conversion between the administered gas and the gas for which it is to work. The final calibration value must correspond to the %L.E.L. of the cylinder divided by the conversion factor.

Let’s take an example:

Target gas: LPG

Conversion factor: 0.65

Cylinder: Methane, %L.E.L 34%.

Mathematical formula: 34 (%L.E.L. of cylinder) divided by 0.65 (conversion factor of target gas) = 52

If, after completing the SPAN calibration process, the value obtained is 52, this means that the detector is correctly calibrated.

Entrust the calibration and periodic maintenance of your gas detection systems to Sensitron

Our gas detection systems have different maintenance requirements depending on the gases detected and the applications in which they are used. Scheduled maintenance ensures the efficiency of gas detection systems with the resulting safety of workers and environments.

Entrusting periodic maintenance to our team means extending the life cycle of the instruments with an impact on both running costs and the environment.

Discover our products

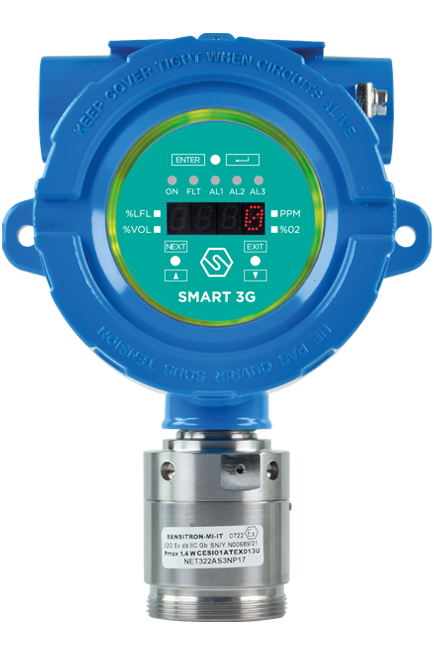

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.

Certified ATEX, IECEx and SIL2/3

SMART 3G D3

Suitable for detecting in classified areas, Certified ATEX, IECEx and SIL2/3, allows non-intrusive field calibration.

MULTISCAN ++S1/++S2

Designed to meet the widest demand from the market, they allow management of up to 264 detectors. ATEX and SIL certified.