In today’s industrial landscape, safety is no longer just a regulatory obligation, but a strategic element that determines the competitiveness of companies. In particular, gas detection is an essential pillar to ensure industrial safety, regulatory compliance and business continuity.

But why is gas detection important?

The presence of toxic, flammable or asphyxiating gases poses a serious risk to workers and company facilities. Implementing an effective gas monitoring system offers numerous advantages:

- Protection of people and environments

An advanced gas detection system allows real-time detection of hazards, preventing life-threatening accidents and improving environmental safety. - Operational continuity and cost reduction

Gas leaks can cause plant downtime, financial damage and penalties. Effective monitoring ensures uninterrupted operations and a significant reduction in emergency-related costs - Regulatory compliance and corporate responsibility

Complying with industrial safety regulations (such as ATEX and ISO) is not only a legal obligation, but demonstrates an ethical commitment to employees and stakeholders.

Gas detection and industrial safety

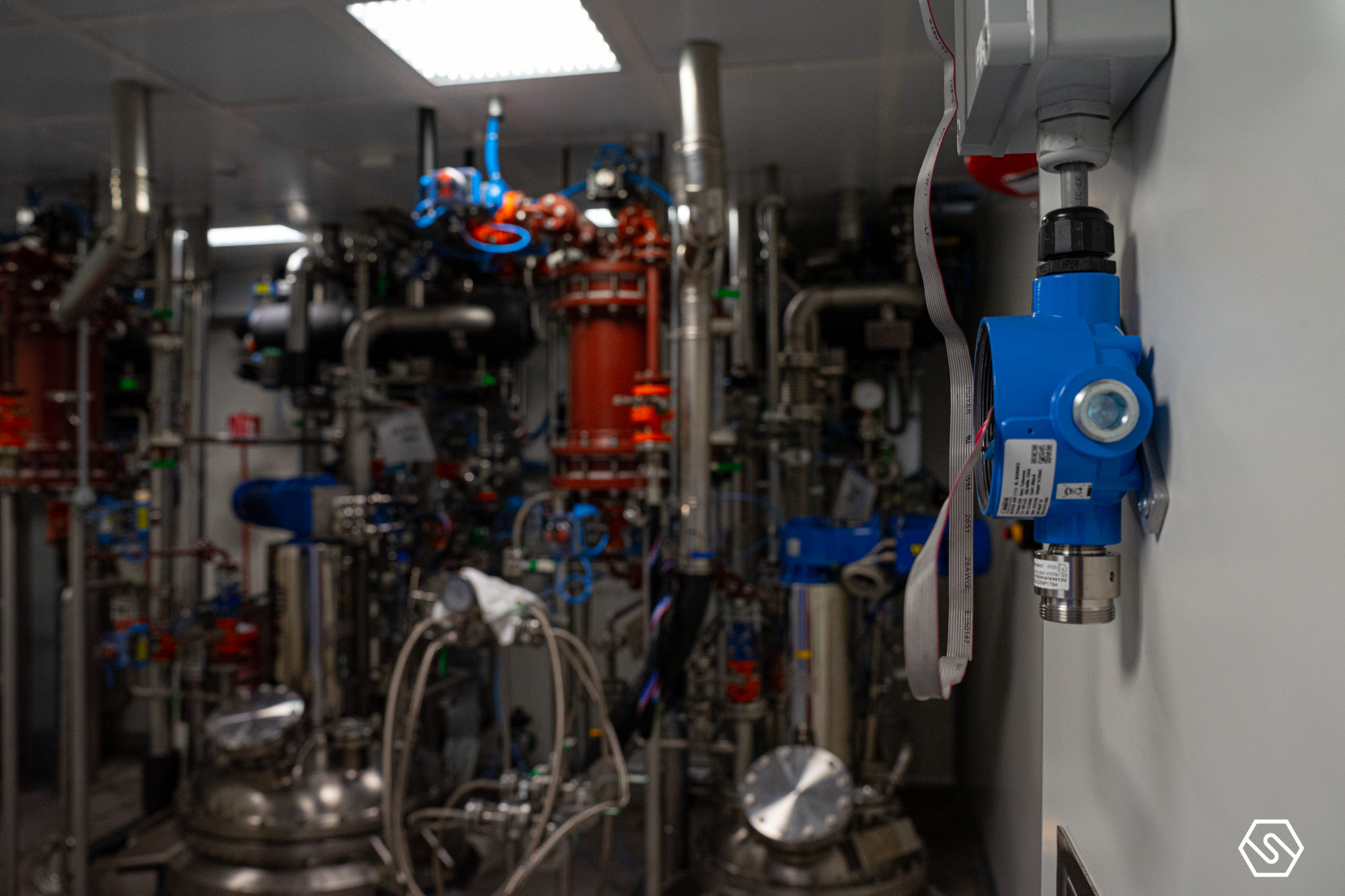

Gas detection is not just a monitoring system, but a key element in ensuring business continuity in complex industrial environments. The integration of modern technologies allows real-time monitoring of environmental conditions, reducing response times in the event of an emergency. Investing in advanced gas detection systems also means optimising production processes, reducing the risks of business interruptions and improving resource management. In addition, accurate monitoring is key to ensuring regulatory compliance, avoiding penalties and protecting corporate reputation.

Sensitron's strengths

Sensitron offers gas detection systems for critical industries such as chemical, petrochemical, pharmaceutical and manufacturing. Our strengths are:

- Innovative Technology: Advanced high-precision sensors for reliable monitoring even in complex environments.

- Solutions for all applications: Tailor-made systems for every application, seamlessly integrated into business processes.

- Quality and Reliability: Certified, tested products designed to reduce extraordinary maintenance.

Investing in security: a step towards the future

Companies that consider security as a strategic investment not only protect people and environments, but also improve their competitiveness. Sensitron, with its experience and commitment to excellence, is the ideal partner for those who want to make gas detection a strategic asset for their business.

Discover our produtcs

Sensitron gas detection systems are suitable for use in any application:

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.ATEX, IECEx and SIL2/3 certified.

SMART 3G D3

Suitable for gas detection in classified areas, ATEX, IECEx and SIL2/3 certified, allows for non-intrusive field calibration.

SMART 3G C3

Suitable for gas detection in classified areas, ATEX, IECEx and SIL2/3 certified, allows for non-intrusive field calibration.