In the environmental and industrial safety sector, the monitoring of hazardous gases is a top priority. Volatile organic compounds (VOCs) pose a significant threat in many working environments, making the use of advanced technologies for their detection essential. Among these, Photoionisation Detector (PID) sensors stand out for their sensitivity and effectiveness in detecting a wide range of chemical compounds.

How do PID sensors work?

PID sensors use photo-ionisation technology to detect VOC gases. The process is performed by an ultraviolet (UV) lamp that emits light with sufficient energy to ionise the gas molecules in the air. This ionisation generates a measurable electric current proportional to the concentration of the gas detected.

This technology allows the detection of very low concentrations of VOCs, making PID sensors an indispensable tool for environmental monitoring and industrial safety.

Benefits of PID sensors

PID sensors offer several advantages over other sensing technologies:

- High sensitivity: They detect VOC concentrations at very low levels (down to parts per billion, ppb).

- Fast response: They provide real-time measurements, enabling timely intervention.

- Wide detection range: They can identify a wide variety of volatile organic compounds.

- Low maintenance: Thanks to their advanced technology, they require minimal maintenance compared to other gas sensors.

- Reliability and durability: Designed for industrial environments, they guarantee high performance even in harsh conditions.

PID Sensor Applications

PID sensors are used in numerous sectors, including:

- Chemical and pharmaceutical industry: For emission monitoring and worker protection.

- Petrochemical industry: For the detection of VOCs in refining and storage processes.

- Environmental remediation: For identifying contamination by solvents and other organic compounds.

- Manufacturing sector: For air quality control and safety in production processes.

- Emergency services and first response: For the rapid detection of hazardous substances in the event of industrial accidents.

Sensitron and the use of PID sensors

Sensitron designs advanced solutions for gas detection. Our PID sensors provide excellent performance and reliability in any industrial environment. Through an ongoing commitment to research and development, Sensitron continues to innovate to offer safety tools that are increasingly effective and easy to integrate into monitoring systems.

Discover our produtcs

Sensitron gas detection systems are suitable for use in any application:

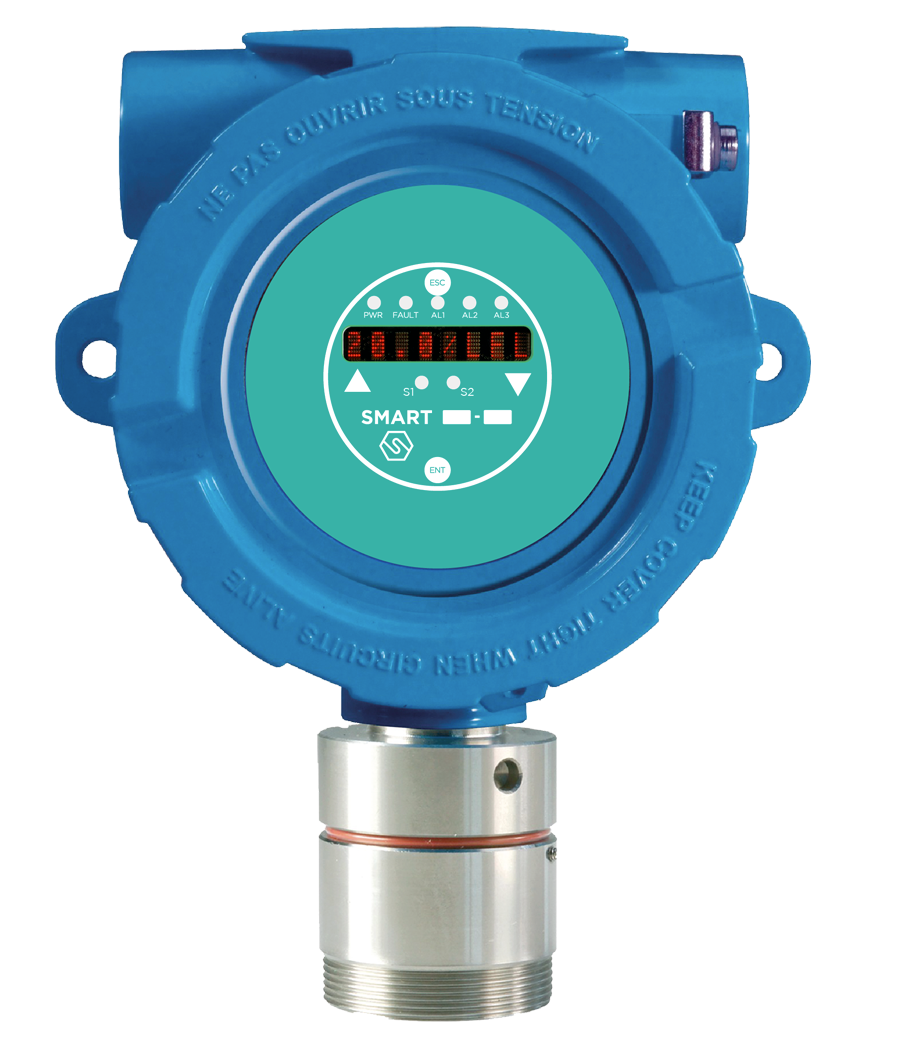

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.ATEX, IECEx and SIL2/3 certified.

SMART 3G D3

Suitable for gas detection in classified areas, ATEX, IECEx and SIL2/3 certified, allows for non-intrusive field calibration.

SMART S-SS

Designed to meet the harshest industry standards, ATEX and SIL2/3 certified, it can mount a HART modem.