Toluene and gas detection in the pharmaceutical industry

Toluene is an organic solvent widely used in the pharmaceutical industry for the synthesis of active ingredients, extraction of compounds and other laboratory operations. Despite its usefulness, toluene poses significant risks to human health and the environment, making its detection and monitoring in industrial processes crucial.

Toluene detection, why it is important

Exposure to toluene can cause a range of health problems:

- Acute: Eye, nose and throat irritation, headaches, dizziness and confusion.

- Chronic: Central nervous system damage, liver and kidney effects, and potential reproductive effects.

Inhalation of toluene vapor is the most common route of exposure, making monitoring of its presence in the air within work environments crucial.

Toluene: most common uses

Toluene has chemical and physical properties that make it suitable for a wide range of applications, including:

Toluene has chemical and physical properties that make it suitable for a wide range of applications, including:

- Chemical synthesis: it is used as a reagent or solvent in chemical synthesis reactions to produce various drugs and active pharmaceutical ingredients. It is essential in processes such as nitriding, chlorination and other organic reactions.

- Benzaldehyde and phenol production: toluene is oxidized to obtain the chemicals used as intermediates in various syntheses.

- Compound extract: used to extract active ingredients from plants and other natural materials because of its ability to dissolve a wide range of organic compounds.

- Solvent for laboratory reactions: in chemical and pharmaceutical laboratories, toluene is frequently used as a solvent for a wide range of chemical reactions and for cleaning equipment.

Benefits of using toluene

Toluene has several characteristics that make its use advantageous:

Toluene has several characteristics that make its use advantageous:

- It effectively dissolves many organic compounds, making it an ideal solvent for various industrial applications

- It is widely available and relatively inexpensive, making it a very viable one.

- Toluene’s volatility and relatively low boiling point make it easy to remove from end products by evaporation.

Technologies used for toluene detection

A PID technology sensor can be used for the proper detection of toluene. Its lifetime depends on various factors, including the quality of the sensor itself, operating conditions and frequency of use. However, key elements, such as the UV lamp, have life cycles ranging from 6 to 12 months, necessitating maintenance for replacement. In addition, depending on the manufacturer’s instructions, periodic calibration of the detector will also be necessary to ensure accurate detection.

Discover our products

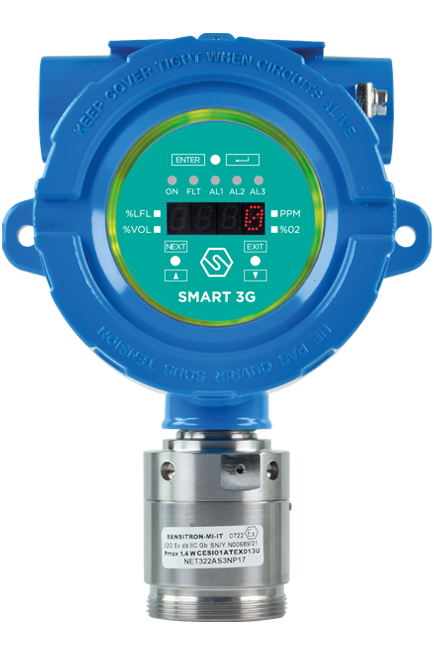

SMART 3G series detectors are ideal for toluene detection in both classified and unclassified areas:

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.

Certified ATEX, IECEx and SIL2/3

SMART 3G D3

Suitable for detecting in classified areas, Certified ATEX, IECEx and SIL2/3, allows non-intrusive field calibration.

SMART 3G C2

Suitable for detecting, in classified areas, the presence of flammable substances (% LFL), toxic gases in ppm, refrigerant gases or for the detection of oxygen deficiency or excess.